Plastic Waste to Fuel Conversion information of project report

Project Title: Plastic Waste to Fuel Conversion

1. Introduction

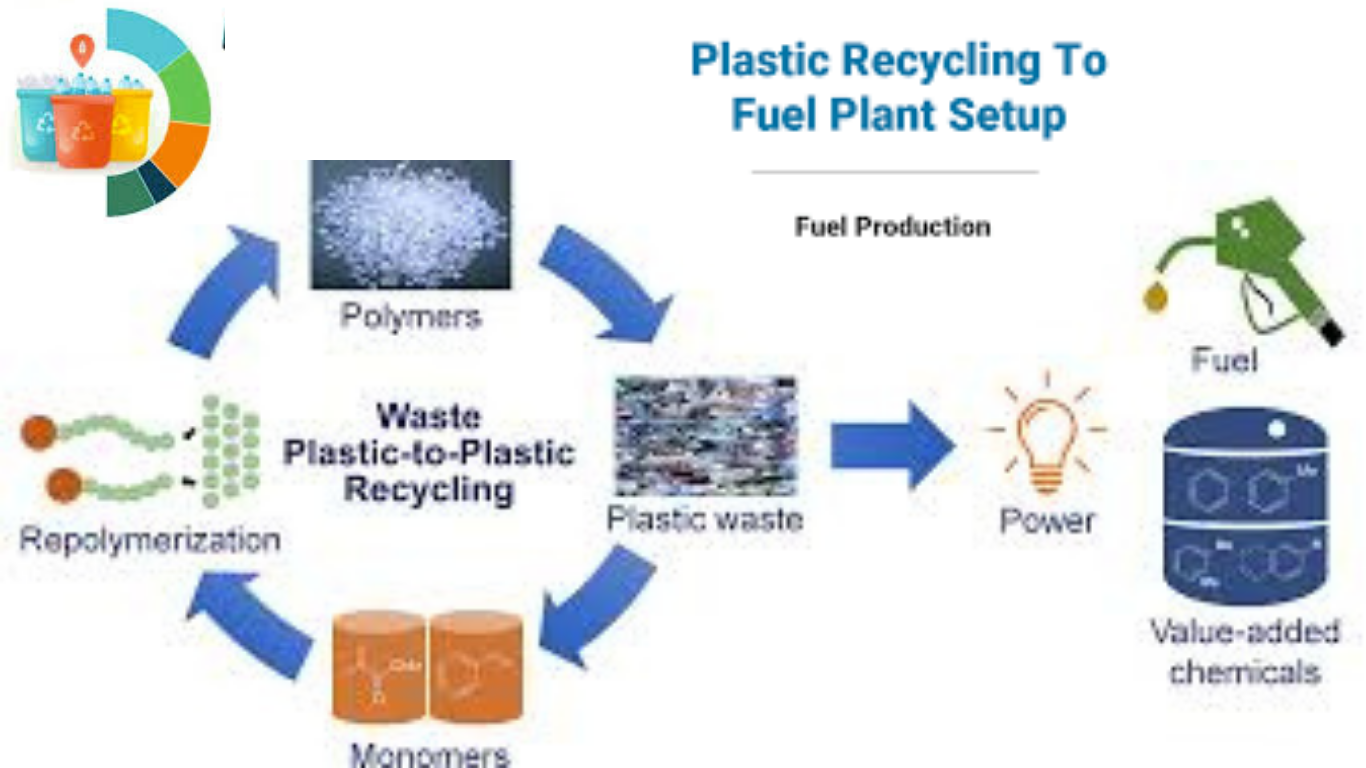

Plastic waste is a major environmental concern due to its non-biodegradable nature. Converting plastic waste into fuel provides a sustainable and economically viable solution for waste management and energy generation.

2. Objective

To reduce plastic waste through a sustainable process.

To produce usable fuels (diesel, petrol, gas) from plastic waste.

To create an eco-friendly alternative to traditional waste disposal methods.

3. Scope of the Project

Collection and segregation of plastic waste.

Processing plastic waste using pyrolysis or other technologies.

Recovery and refinement of fuel products.

Utilization or sale of the produced fuel.

4. Types of Plastic Used

Polyethylene (PE)

Polypropylene (PP)

Polystyrene (PS)

Polyethylene Terephthalate (PET) — limited use due to by-products

Polyvinyl Chloride (PVC) — usually avoided due to toxic emissions

5. Technology Used

Pyrolysis Process

A thermal degradation process in the absence of oxygen.

Temperature range: 300°C–500°C.

Converts plastic waste into:

Liquid fuel (pyrolysis oil)

Gas (used to heat the reactor)

Char (residue)

6. Process Flow Diagram (Simplified)

Collection & Sorting

Shredding

Feeding into Reactor

Heating (Pyrolysis)

Condensation of Vapors

Fuel Storage

Gas Recycling/Emission Control

7. Output Products

Liquid Fuel (Pyrolysis Oil) – Can be refined into diesel or petrol.

Non-condensable Gas – Reused for heating the system.

Char/Carbon Black – Used in construction or as a filler.

8. Benefits

Reduces plastic pollution.

Generates energy/fuel from waste.

Lower carbon footprint than incineration.

Creates job opportunities.

9. Environmental Considerations

Emission control systems required.

Proper disposal or use of char.

Avoidance of PVC due to chlorine content.

Regular monitoring for dioxins and furans.

10. Economic Feasibility

Moderate capital investment.

Profit from selling fuel and by-products.

Government subsidies or carbon credits may apply.

11. Challenges

Sorting and cleaning of plastic waste.

Emissions control and regulation compliance.

Public awareness and supply chain setup.

12. Conclusion

The plastic-to-fuel conversion process presents a promising approach to address both energy needs and plastic waste management. With the right technology and environmental safeguards, this project can contribute significantly to sustainable development.